FINE BLANKING

What us "FINE BLANKING"?

FINE BLANKING is a new technology of press manufacturing that uses high-pressure principle in hydrostatic pressure

that line up the metal texture and receive clean profile without creating breakdown.

that line up the metal texture and receive clean profile without creating breakdown.

Feature of FINE BLANKING

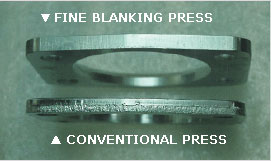

- Can gain 100% clean profile

- Can obtain precise measure and location

- Obtains minmum number of die roll

- Plane limit increases

- No change in measurement caused by regrinding since it obtains minimun number of clearance

- No use for machinery manufacturing such as Milling, Drilling, Reaming after the press manufacturing process

- Can perform forming manufacturing processes such ah Bending, Offset, Coining, and Extrusion.

- Decrease in prime cost as many manufacturing processes diminishes

- Can omit heat treatment process as profile hardness increases.

- Can obtain precise measure and location

- Obtains minmum number of die roll

- Plane limit increases

- No change in measurement caused by regrinding since it obtains minimun number of clearance

- No use for machinery manufacturing such as Milling, Drilling, Reaming after the press manufacturing process

- Can perform forming manufacturing processes such ah Bending, Offset, Coining, and Extrusion.

- Decrease in prime cost as many manufacturing processes diminishes

- Can omit heat treatment process as profile hardness increases.

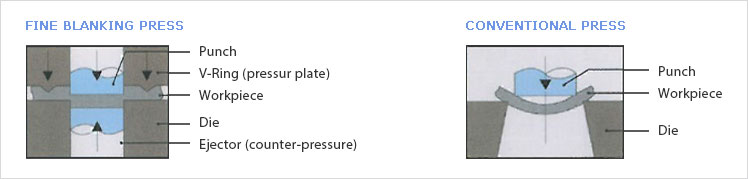

FINE BLANKING operation principle

|

The raw material insert to F/B FINE BLANKING method is new press technology, which flows metallic structure by high-pressure theory under static water pressure and get the clean front cut end and doesn’t cause any vibration or wave cut end. |

|

- The operates pressing to 20~40% for material fixed to the mold(Guide plate , Die plate)

- The counter pressing 10~20% for prevent reverse bending during main punch process(Counter punch)

- The main power punches (50-80) is activated than F / B Press Finishing Process.

- The counter pressing 10~20% for prevent reverse bending during main punch process(Counter punch)

- The main power punches (50-80) is activated than F / B Press Finishing Process.

Technical comparison